Together we exceed any limitations of 3D printing

The moral of this story: exceeding restrictions together takes us further. What comes to AM, you have no reason to “carry coals to Newcastle” – or, as we would say in Finnish: “ it does not pay off to go further than the sea to fish.”

The use of additive manufacturing (AM) in spare part business is snowballing in many sectors. AM enables the life cycle extension of the machine or equipment by providing spare parts fast, decentralizing manufacturing, and reducing inventory. Moreover, it is applicable even for single components and saves time and money while it requires no molds or other costly preparations.

Metal printing calls for design rules

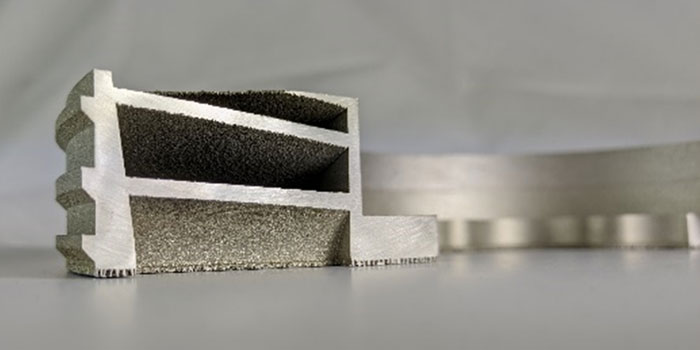

The metal printing nature, however, calls for specific design rules. One rule of thumb has been building angles lower than 45 degrees only with a support structure. Supports conduct away the heat generated by the process, and they also prevent distortions in parts. The problem is that the support structure increases the printed material, so it raises the price. Supports also need to be removed, which can be costly or sometimes even impossible.

Reality does not follow rules

Huld AM team faced this limitation with a customer spare part having thin blades with low build angles. These blades were 2 mm thick with build angles as low as 13°. The low angle was not the only challenge as the component geometry also dictated that these angles were present in all directions, and the part could not be oriented to reduce crash risk during the build. Like in most cases, with spare parts, changing design was not an option. Huld found a solution to fulfill the customer need but, for the future, initiated a development project with #Delva, with a target to print low-angle parts without a support structure. Delva had overcome the challenge in many customer cases, both spares and new components, but an angle this low required special forces. Delva started a target-oriented dialog with EOS.

Customer needs are decisive

Like Huld and Delva, EOS is a genuinely customer-oriented company. The technology is not there for itself but to fulfill the customer needs. The company’s efforts to encourage sustainability and responsible manufacturing underline this. A development project was started at EOS to find the right process parameters to build low angles in different directions successfully. The theory and practical knowledge provided a good foundation, determination concretized in tireless testing. As a result, EOS solved issues with the low angle by optimizing process parameters and implementing innovative exposure strategies. EOS, Huld, and Delva make together these structures – and much more – available in Finland locally.

Huld is a company offering an internationally unique combination of software and product development expertise, building intelligent solutions that last for tomorrow – and beyond. Huld has years of experience working on additive manufacturing with industrial partners. Huld is eager to find answers to complex tasks and push the additive manufacturing industry forward with seamless co-operation.

Delva Oy is an experienced expert and partner in industrial metal printing. In addition to the printing service, Delva offers deeper co-development to find optimal solutions for individual needs. 3D printing of metals adds a new dimension to the range of manufacturing technologies and enables entirely new structures and solutions. Delva Oy and its networks support companies from the beginning to finished, if wished, post-processed components. Deep material expertise, Finland’s broadest material offering, and insight help significantly increase printing benefits. Metal prints from Delva Oy for tough use.

EOS is the leading technology provider worldwide for industrial 3D printing of metals and plastics. With innovative EOS systems, it is a technology and quality leader for high-end solutions in additive manufacturing (AM). Founded in 1989, it is the pioneer in direct metal laser solidification (DMLS) and provides highly productive systems for additive manufacturing with plastics. The portfolio also includes worldwide service and comprehensive consulting offers.