PPWR in Industrial Packaging – Increasing Sustainability with Every Package

Packaging and Packaging Waste Regulation (PPWR) is coming – start preparing for the change with Huld’s packaging professionals.

In April 2024, the EU reached a preliminary agreement on the Packaging and Packaging Waste Regulation (PPWR), marking a significant milestone in the journey towards more sustainable packaging practices.

The final vote on the regulation is anticipated for September or October of 2024, after which the regulation will be implemented. These upcoming changes mark interesting times for the packaging industry.

Insight into Industrial Packaging

While much has been written from the viewpoint of consumer and food packaging, insights into industrial packaging have been harder to find. The coming regulation focuses on volume packages, which are mainly found in consumer and food sector, but the industrial side falls under the same set of rules. The regulation has not yet been implemented and many practicalities will be defined in the coming years. However, it is prudent to start preparing and focusing on sustainability in advance.

To this overview, I have compiled five key points I found most relevant – and many details and exceptions have been left out. Note that this blog has been compiled by a single packaging expert, so if you disagree with my interpretation, please let us know and we’ll look into it.

Reasons Behind the PPWR

The old Packaging Waste Directive from 1994 has not effectively controlled the amount of packaging waste generated in the EU. As waste levels rise, so does the environmental burden. Differing national legislations have also hindered packaging innovations from crossing borders and becoming profitable.

The new regulation, PPWR, requires uniform compliance across the EU, with some room for country-specific actions. Its ultimate target is to turn the trend of rising levels packaging waste and support circular economy. The targets for overall packaging waste reduction, compared to 2018 levels, are 5% by 2030, 10% by 2035, and 15% by 2040.

Look into PPWR

From 2030, all new packaging within EU borders must be recyclable. Packaging material must be minimised, and reusable packaging should be used when possible. Target percentages are assigned to different packaging groups based on their potential.

Plastic packaging, due to its emerging recycling technology and low levels of recycled stock, is the most heavily regulated in all aspects. Many specifications, standards and further assessments are set for coming years, so the full impact of the regulations remains to be seen.

1. Recycling

The EU has previously set overall recycling targets for common waste materials. Despite Finland’s accustomed recycling habits, we are likely to fall behind in plastic targets set for 2025. This highlights why plastic is the only material with mandatory targets. Recycling rates of other materials will be monitored, and targets may be defined later.

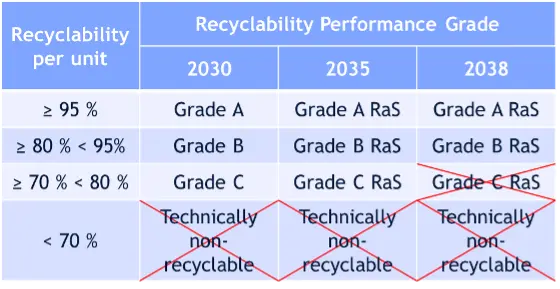

Starting from 2030, all packaging will be divided into performance grades according to their recyclability. Packaging with recyclability below 70% will be considered non-recyclable and cannot be used within the EU. From 2035, recyclability will be assessed by new “recycled at scale” criteria and by 2038, all packaging must achieve at least Grade B (80% or higher) recyclability.

The criteria and performance grades will be defined in the coming years, so we will have to wait and see how this impacts our mostly used materials. Innovative packaging can be given a 5-year reprieve from recyclability requirement, given that a clear ecological benefit can be proven and the recycling technology is available at the end of the time period.

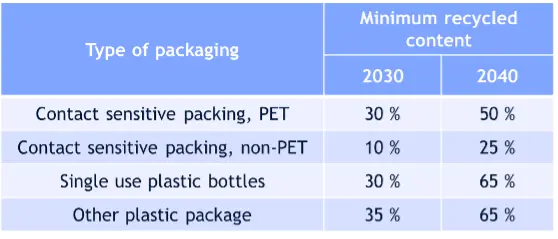

For plastic, the regulation mandates levels of recycled material (from post-consumer plastic waste) used in all packaging. For “other plastic packages”, the targets are 35% by 2030 and 65% by 2040.

These levels are measured per manufacturer annually, allowing varying levels across product offering. This aspect can be relatively easy to achieve, if there is enough recycled material to use, and we accept that the products containing recycled material may differ visually, but still function well.

2. Re-use

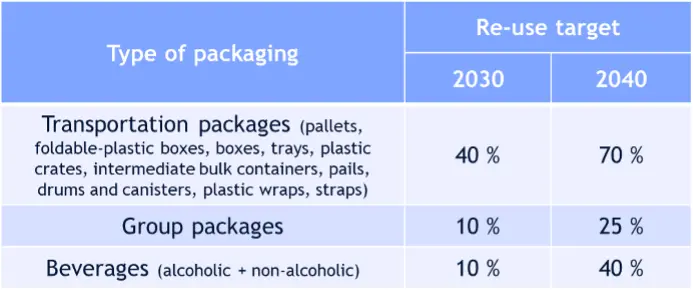

Establishing reuse systems for packaging, when viable, is a major goal of the regulation. This impacts the waste generation directly and is frequently discussed regarding PPWR and its changes. For transport packaging, the overall reuse target is 40% by 2030 and 70% by 2040.

The regulation mandates that transport packaging used between different sites of a company within the EU, or to deliver goods to another economic operator within a country, must all be reusable. Exceptions include cardboard boxes, packaging for dangerous goods, and custom-designed packaging for large-scale machinery and equipment.

A country may be exempted from re-use goals if they reach certain recycling targets, but Finland will not be likely to meet them. However, we don’t have to start from zero, as for example re-usable EPAL standard pallets are used in every warehouse already.

3. Minimisation

The key item for industrial packaging design in this regulation is minimisation. The volume and weight of each package must be as small as possible, while maintaining protective function and recyclability. In group and transport packages, the ratio of empty space is limited to 50%. Packaging with double walls, false bottoms, and other features aimed at making the package look bigger, are explicitly forbidden.

A document must be created to assess minimisation efforts according to performance criteria. Minimising the material used for manufacturing an item, not only material of the packing item itself but also waste generated, is already a very important part of the design as it also directly impacts the cost. It will be interesting to see what kind of guidelines are given for the minimisation itself, and how recyclability grades will affect preferences of material choices.

4. Labelling

Packaging will receive new labelling with clear pictograms for waste stream identification. The same symbols will be used in waste receptacles. Harmonized symbols for recycled content and bio-based plastic content will be available but are not mandatory. These new labelling rules do not apply to transport or reusable packaging.

5. Responsibilities

Every operator in the supply chain has a role in ensuring compliance with PPWR. Most documentation and assessment burdens fall on the “manufacturer,” but who that is depends on the compilation of the individual package unit. Moreover, the regulation cannot be bypassed by acquiring packages outside the EU. All packaging crossing EU borders must comply with the same rules, and importer is responsible of guaranteeing compliance.

Ultimately, it is up to us, as packaging professionals and consumers, to help reach these goals with our everyday actions, or stricter restrictions may be needed in the future.

Do you believe there is additional work required to achieve these goals, or would you like to engage in a more in-depth discussion about how these changes will impact your company? Please contact your Huld sales representative or Jasperi Kuikka, and we will assist you in preparing for the upcoming changes.

Contact

Jasperi Kuikka

jasperi.kuikka@huld.io

+358 45 349 0665