There’s no limit – we design products from scissors to satellites, from concept to manufacturing.

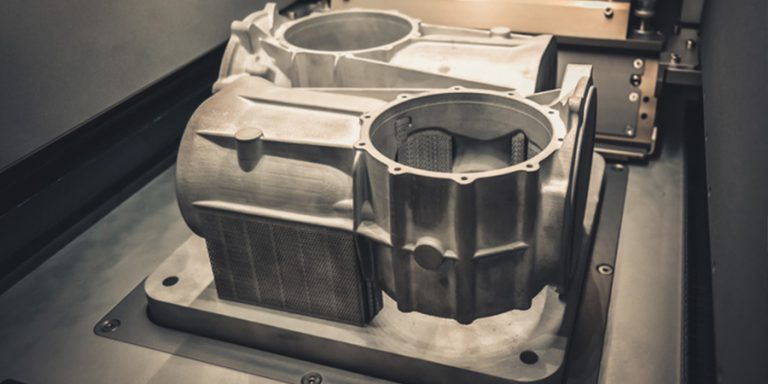

We focus our Mechanical Design know-how on one or few areas and know them well to secure the quality and expertise. Our expert teams know what it takes to build innovative products and make them ready for production. We value form, functionality and efficiency in both design and manufacturing.