Prototypes were tested with real users

Customer evaluated all the concepts and the best ideas were selected for prototyping phase. Huld’s experts designed all the details for the selected concepts and a small series of prototypes were then manufactured. They were tested in real delivery work.

“We got valuable feedback and comments. After the prototyping phase it was easy to optimize these delivery racks and improve the design”, comments Design Manager Hannu Havusto from Huld.

Simple and light design improved the usability

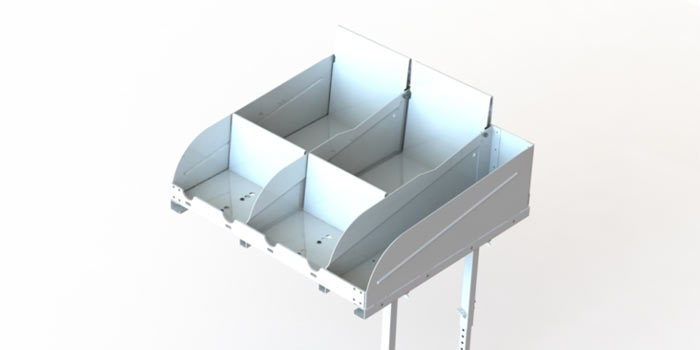

After user testing, two of the sorting rack concepts were selected for further and wider field-testing for its structure and size. Field-tests provided valuable data and the prototype rack was updated based on the data.

The goals of the mechanical design of the rack were to reduce the quotient to a minimum by taking advantage of the possibilities brought by the sheet metal. The manufacturability of the rack was better taken into account, which reduced production costs and quotients, as well as simplified the structure and improved functionality. Usability also improved when the structure was dimensionally modified and made stronger. Other functions were also integrated into the structure, which significantly reduced the time required for the final assembly.

Active communication and flexible changes

Throughout the collaboration, Huld’s project team was in constant contact with the customer, listening to new needs and bringing up new solution for the product design. The customer’s wishes about the mounting of the stand and the necessary operating variations and usability were flexibly incorporated into the products.

“Creating common understanding of Posti process needs created a good base for straightforward actions”, comments Kari Tuomola.

Delivery racks have been ordered for several Post offices for trial use and the feedback has been positive. First new model got final acceptance and the second new model is in last testing phase and most likely to get acceptance. One user commented that the second delivery rack model is clearly the best rack that has ever been used.

“We are happy that after Posti’s 382 years of operation we still find things to improve”, comments Tuomola.