Additive Manufacturing

Unleash efficiency by optimizing performance, using less natural resources, and manufacturing only on demand, with additive manufacturing.

Unleash efficiency by optimizing performance, using less natural resources, and manufacturing only on demand, with additive manufacturing.

Additive manufacturing offers unique opportunities to create better and more sustainable products – and why would you settle for anything less. We have helped our customers utilize AM by turning innovations to success stories.

Whether you need support in your initial concept design or simulation driven optimization – or anything between – we have a solution for you.

We assess your needs and identify opportunities where additive manufacturing can make a difference.

From concept development to the optimization of end products, we do the designing for you with high quality, and ensuring manufacturability.

Ensure your team takes full advantage of additive manufacturing. We offer runway by sharing knowhow and the best practices, collected from dozens of projects.

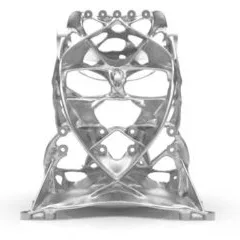

Welded aluminum plates were no option for this demanding industrial application. Additive manufacturing achieved weight reduction of 80% and combined 17 parts into one.

Intelligent sensor was embedded inside a metal AM casing for a space mission. Solution performance was tested in space environment.

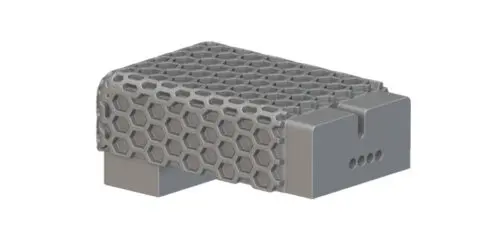

Machining is accurate, and additive manufacturing is flexible. Why not to use both of them in the same product?

Better function, less parts and 30 % cheaper price was achieved.

Unique monitor holder was designed and delivered in under 3 weeks from customer request with additive manufacturing.

The focus was on usability and appealing look. It was manufactured within a fraction of the time the customer was used to.

600 bar pressure requirement and harsh environment were no issues for 3D-printed metal parts. Additive manufacturing was a clear choice to produce complex internal channels and reduce manufacturing cost.

No more obsolete spares. On demand manufacturing and more competitive spare parts with less time spent on waiting. Our AM team is proud to support several industrial companies to:

Sales Director, Product Design

jasperi.kuikka@huld.io

+358 45 349 0665